Pipe Patch

Trenchless Repair Technology

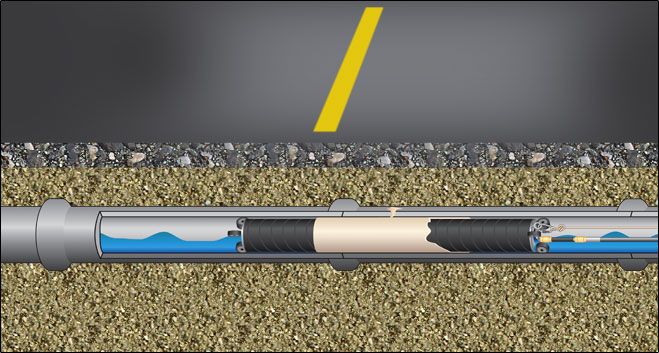

Cured-in-Place Pipe (CIPP)

CIPP Cured-In-Place Point Repair is a process where a liner is inserted into a pipe impregnated with a thermosetting resin, which is expanded and cured to form a tight-fitting liner within the host pipe, a pipe within a pipe.

The CIPP process incorporates the existing pipeline into the finished product to produce improved performance of the original pipeline. Although cure times vary due to host pipe material and temperatures, PipePatch is typically cured in 1 to 3 hours.

Point Repair

Point Repair is PipePatch’s cost saving process of lining only the areas that require repair versus lining the entire length of pipeline. PipePatch’s point repair system not only saves material costs but also man-hours. Depending on the pipes diameter, PipePatch requires only 1 to 3 technicians to complete a repair.

Structural Integrity

PipePatch restores structural integrity to damaged pipes and exceeds Specification ASTM F1216 for Cured-In-Place-Pipe (CIPP). This Specification requires our materials to be tested for a minimum service life of 50 years. Our fully cured resin serves as a barrier between the damaged pipe and the flow, or as a stand-alone pipe.

Increased Flow Capacity

PipePatch provides the least reduction of all point repair methods used to rehabilitate pipes. When cured, PipePatch is only 1/8 inch thick. The smooth interior of our product with tapered ends typically improves flow capacity. The smooth interior also provides excellent corrosion and abrasion resistance.

Proudly Serving the Northwest Ohio Area

Including Bowling Green, Findlay, Napoleon and Toledo